Analytics powered by artificial intelligence (AI) and machine learning are applied to the data in real time – and insights are leveraged to improve decision-making and automation in every area of supply chain management: supply chain planning, logistics management, manufacturing, R&D and engineering, enterprise asset management (EAM), and procurement. Big Data and AI analytics: In Industry 4.0, Big Data is collected from a wide range of sources, from factory equipment and Internet of Things (IoT) devices, to ERP and CRM systems, to weather and traffic apps.

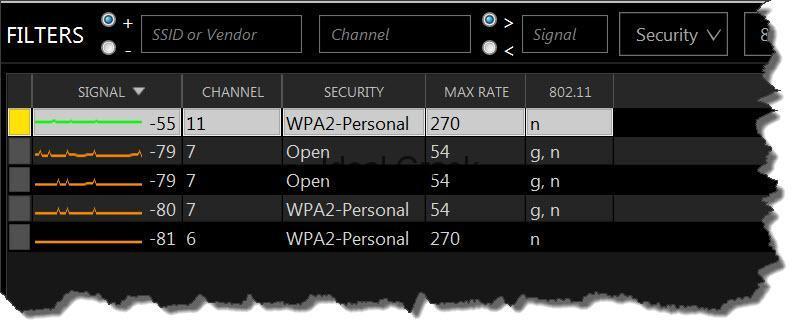

Inssider 4.0 need key full#

Businesses and supply chains already use some of these advanced technologies, but the full potential of Industry 4.0 comes to life when they’re used together.

These innovations bridge the physical and digital worlds and make smart and autonomous systems possible. Industry 4.0 is built on nine technology pillars. “The general definition of Industry 4.0 is the rise of digital industrial technology … Industry 4.0 transformations allow us to work alongside machines in new, highly productive ways.” Daniel Burrus Industry 4.0 technologies

Ultimately, Industry 4.0 is a major part of any company’s digital transformation. It inter-connects with back-end systems, like enterprise resource planning (ERP), to give companies an unprecedented level of visibility and control. But Industry 4.0 doesn’t stop at the supply chain. Industry 4.0 makes everything in your supply chain “smart” – from smart manufacturing and factories to smart warehousing and logistics. Industry 4.0 is powered by the Industrial Internet of Things (IIoT) and cyber-physical systems – smart, autonomous systems that use computer-based algorithms to monitor and control physical things like machinery, robots, and vehicles. We are now in the Fourth Industrial Revolution, aka Industry 4.0, which revolutionizes the automation, monitoring, and analysis of supply chains through smart technology. The reason they were called industrial “revolutions” was because the innovation that drove them didn’t just improve productivity and efficiency a little bit – it completely revolutionized how goods were produced and how work was done. Each was powered by a disruptive new technology: the mechanics of the steam engine, the innovation of the assembly line, and the speed of the computer. Since the 1800s, we have experienced three industrial revolutions. Governance, Risk, Compliance (GRC), and CybersecurityĮngineering, Construction, and Operations Accounts Receivable, Billing and Revenue Management

0 kommentar(er)

0 kommentar(er)